MIXING TECHNOLOGY

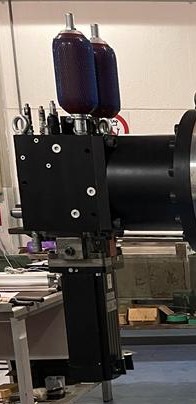

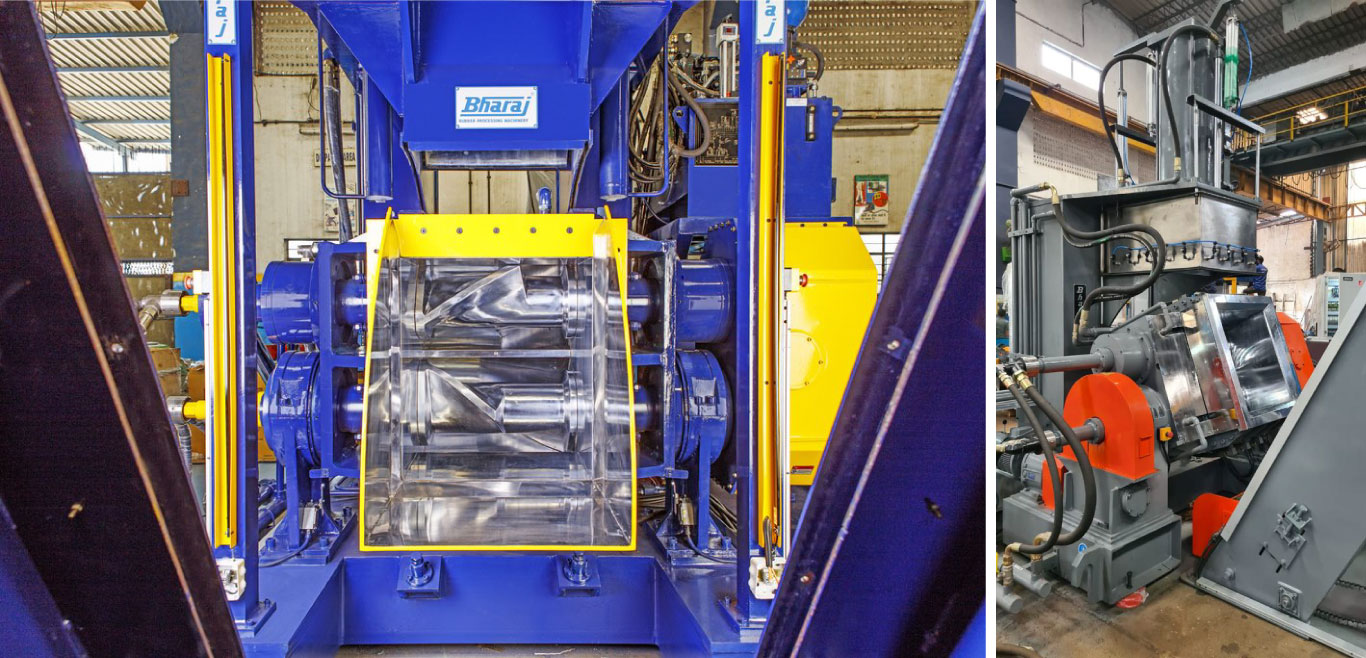

Kneader:

Mixing machine for the discontinuous production of rubber, silicone or plastic material compounds with two counter-rotating horizontal rotors in a mixing chamber.

The Kneader, compared to an internal mixer, has the characteristic of having the mixing chamber with a hydraulic tipping system to facilitate the unloading and cleaning phase

Machine

SILICONE

KNEADER

RUBBER

KNEADER

Integrated "ENERGY SAVE" system

Reduced co2 emissions from machinery

|

MODEL No. |

DRIVE MOTOR HP/RPM |

MAX SPEED RPM |

CHAMBER VOLUME IN LITERS |

EFFECTIVE WORKING CAPACITY |

TILTING ANGLE |

TIPPING DRIVE POWER |

|

KNT 5 |

8 KW |

15 Litri |

05 Litri |

130° / 145° |

2 KW |

|

|

KNT 10 |

15 KW |

25 Litri |

10 Litri |

130° / 145° |

2 KW |

|

|

KNT 25 |

22 KW |

30/35 RPM |

40 Litri |

20 Litri |

130° / 145° |

2 KW |

|

KNT 35 |

45 KW |

30/35 RPM |

75 Litri |

35 Litri |

130° / 145° |

2 KW |

|

KNT 55 |

60 KW |

30/35 RPM |

125 Litri |

55 Litri |

130° / 145° |

2 KW |

|

KNT 75 |

100 KW |

30/35 RPM |

170 Litri |

75 Litri |

130° / 145° |

2 KW |

|

KNT 110 |

150 KW |

30/35 RPM |

250 Litri |

120 Litri |

130° / 145° |

5 KW |

|

KNT 150 |

150 KW |

30/35 RPM |

350 Litri |

150 Litri |

130° / 145° |

5 KW |

CERTIFIED DESIGN AND CONSTRUCTION