ACCESSORY MACHINES

Conveyor a

basin

"SKIPPER"

Built using new materials, with innovative mechanical technical solutions and customized management software.Telescopic excursion that allows the transport of the material to greater distances in a small size without inhibiting the normal work areas.

Cutting machine

Silicone LOG

NEW LOG SIZE 2021/200.

This machine represents our solution for cutting square or round silicone LOG depending on the need.

Our LOG CUTTER can be positioned for example at the exit of extruders, mixers with double Z reels with discharge screw and filter presses.

The cutting length is carried out by positioning the appropriate through-beam photoelectric sensor at a height; the piston carries out the cut and subsequently the belt accelerates in speed to facilitate the detachment of the cut LOG.

The machine can also, if required, fall within the industry 4.0 plan by opting it with a touch screen control panel, software for collecting and sending production data to management systems, remote management system and recipe book.

This is just one of the machines that JP-TECH builds for packaging raw silicone.

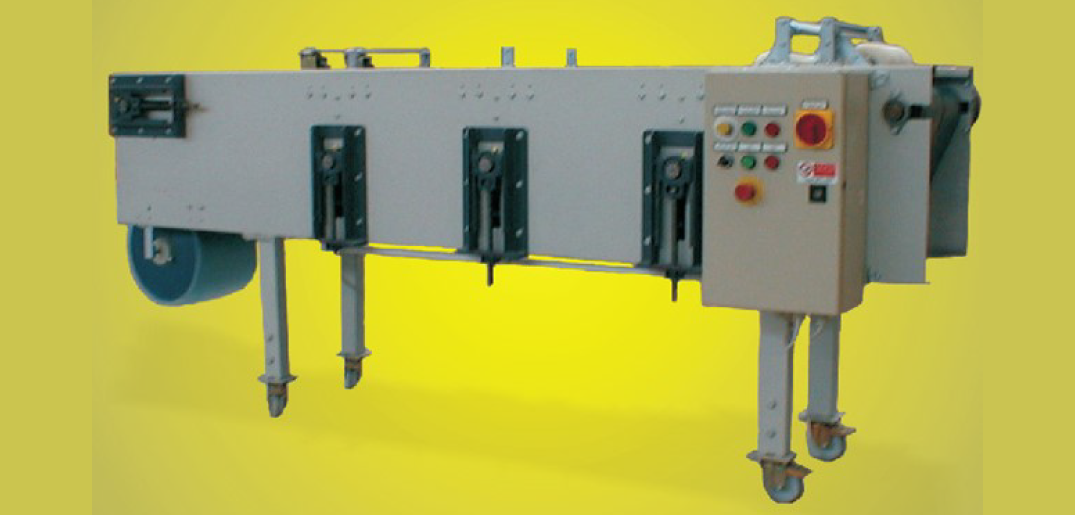

Machine for

polyethylene

The Politene 400 machine is used when the strip cannot be powdered to avoid pollution.

It too can be used by manually and/or automatically adjusting the speed (from 0 to 15 meters per minute).

The start-up operation is extremely simple, and the packaging of the strip wrapped in polythene is always effective.

The machine is mounted on wheels: it therefore allows it to be used in combination with various strip supply lines.

This machine designed and built by us has also attracted considerable interest in all cases where the packaging of powdered and rolled strips (pizzas) is necessary.

The two models differ only in their capacity make pizzas with a maximum diameter of 500 and 800 mm respectively.

The maximum working speed is 20 meters per minute.

This machine also has the option of manual or automatic speed adjustment.

All parameters and functions are programmable from the keyboard; Using the machine is simple and immediate.

The operator sets the desired strip cutting length and then inserts the end of the strip into the appropriate locking system, starts the first plate and begins winding: once the set length has been reached, the machine carries out the cut and the 1st plate ends. 'winding; the operator repeats the wrapping start operation on the 2nd plate and, while this works, frees the 1st plate from the product.

By alternating the two plates the wrapping cycle is continuous, therefore it is never necessary to stop the machine.

CERTIFIED DESIGN AND CONSTRUCTION